Foam Fabrication

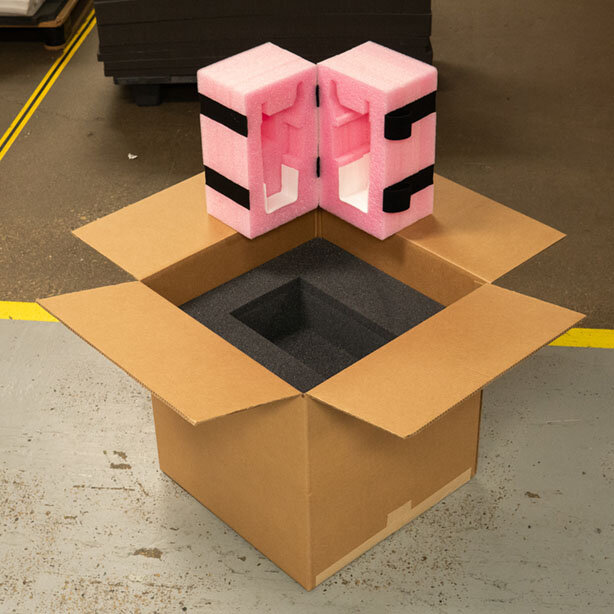

Pak-Rite has broad experience designing and manufacturing foam components ranging from simple pads and end-caps to multi-stage cushioning systems. Our foam assemblies not only provide shock and vibration protection during transit, but they also include other benefits such as organizing parts and offering an attractive product presentation which reflects the quality of your brand.

Assembled using hot melt or cold spray adhesives and heat bond lamination, Pak-Rite specializes in:

Case Inserts

Foam Caps

Foam Assemblies

Foam Pads

Complete Shippers

Shock Absorbing Skid Bases

Foams

Pak-Rite renders a wide variety of foams into precision cut and fabricated custom interiors.

Closed-Cell XLPE Foams

Smooth, professional looking finish

Ideal for Sales/Demo Kits, OEM Packaging & Service Kits

Moderately pliable to rigid densities (1.7# to 6#)

Provides excellent support

Can have chemically resistant properties

Closed-Cell PE Foams

Uniform Textured finish

Ideal for Industrial Fixtures & Kits, Electronic Components

Ester and Ether Open-Cell Foams

Smooth, Open-Cell finish

Ideal for light and impact-sensitive components

Flexible and pliable

Provides excellent shock absorption

MIL-SPEC Foams

We have access to a wide veriety of Military Spec Foams

MIL-PRF-26514

A-A-59136